VILLFORTH SIEBTECHNIK GmbH

Villforth Siebtechnik GmbH is a family business based in Reutlingen, Germany. It has more than 150 years of business tradition.

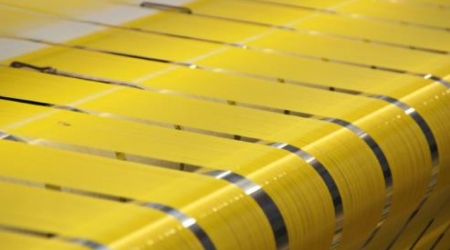

Each forming fabric is made with: excellent raw material, up-to-date weaving technology, committed and highly trained employees, as well as sophisticated machinery technology. The result: custom-made training fabrics that are used for a wide range of applications around the world.

They consider the high quality of their products as their personal responsibility verified by their integrated Quality Management System implemented by each member of their staff. They not only have a relationship of trust within the company but also with their clients.

SYNTHETIC FABRICS IN HIGH-END QUALITY

Precision and quality are their top priorities. Since their foundation in 1870, they manufacture fabrics for forming, dewatering, transportation, pressing, filtration, and embossing. Especially in the field of forming fabrics for paper machines, they count to the leading global players striving to extend their market position. Their high-quality fabrics are being used in various areas. They fully take into account all particular requirements of the specific field to the properties and lifetime of the fabrics requested. A high-tech service by experienced engineers is part of they top products, enjoying a good reputation. It goes without saying that their fabrics, the raw materials used and the production process is 100% Made in Germany. Thay are convinced to provide a custom-made Villforth fabric for even the most challenging applications.

Villforth is one of the world's leading manufacturers of forming fabrics for paper machines.

Application areas:

- Board, liner and fluting, cartonboard: Smooth manufacturing process. Their custom-made high-tech screens are used to get the best out of the wiring section.

- Graphic paper: Its innovative display technology sets high standards in the paper industry worldwide. Its production program includes highly developed forming fabrics for all paper machine types and paper grades.

- Toilet paper or Tissue: Specially developed tissue sieves, their paper becomes even more voluminous, soft and absorbent. At the same time, the best material properties guarantee excellent stability of the sieve, even under the harshest conditions.

- Special Papers: High quality forming fabrics support good printability (decoration/photography base paper) through uniform forming, mark prevention and high compression in relation to a very smooth paper surface.

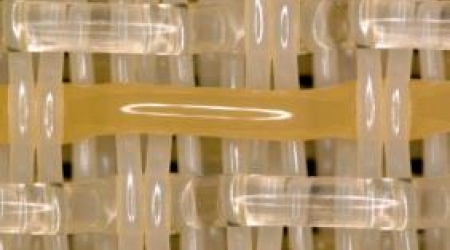

- Nonwoven fabric: Electroconductive fabric with an antistatic finish is used in nonwoven (Airlaid) machines to dissipate the electrical charge created by blowing fibers onto the screen.

- Process Belts: High quality drum liners, with long durability and professional installation by our assembly staff setting high standards.

They would be pleased to advice you in person at your site with one of our highly qualified employees.

For further information visit their website here.